50 YEARS OF PRECISION

Micro-Finish is the result of 50 years of challenges, experience and technical improvements in the service of its most demanding customers.

MICRO-FINISH IS A STORY THAT MOVES FORWARD.

Founded in 1969, our company retains its family soul despite the significant expansion of its tools, skills, services and surfaces. Our facilities are at the cutting edge of today's techniques thanks to a constant research and development process. Our history has been written together with the one of our customers by adapting to the highly technological developments in their sector.

IT'S ALSO MEMORY

DO THE SAME FINISHING AS YOU DID LAST YEAR.

We offer gain in time, reliability and savings to our customers thanks to our ERP (Enterprise Resource Planning), a production management software that guarantees the archiving of more than 50'000 operating sequences. We freeze, archive and retrieve previously applied treatments to guarantee the traceability and repeatability of treatments.

A LASTING COMMITMENT

Our quality commitment to our customers is our best advertisement. Internally, we also take care of the well-being and safety of our staff.

"TAKING CARE AT MICRO-FINISH IS A LEADERSHIP ATTITUDE."

A SUSTAINABLE PROCESS

Our own wastewater treatment plant complies with current environmental standards and above all with our values!

- At the end of 2017, installation of solar panels, on about 600 m2 for a consumption by Micro-Finish: ~ 70%

- In 2019, we have opted for an electric delivery car for our regional destinations

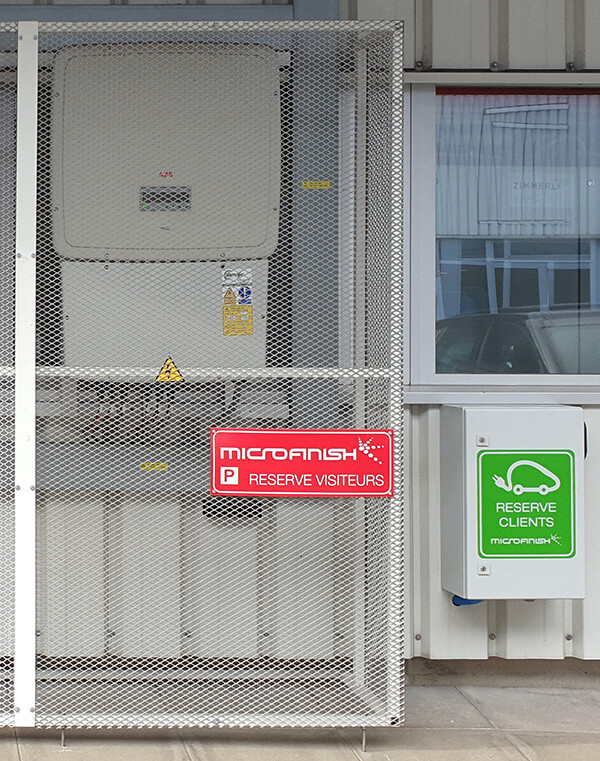

- We have installed a free charging station for electric vehicles for our customers