PRECISION INDUSTRIES

THINK MICRO-FINISH!

What matters to you is the result. Tell us your parameters, we will do the rest. Home-made and family secrets, it is our job with complete transparency!

Our microfinishing has been specially developed for an industry requiring high precision and reliability on extremely sensitive parts.

DEBURRING

Bulk treatment by sandblasting or tribofinishing.

BURR REMOVAL

TREATMENT ON ALL TYPES OF PARTS (HOLES, KNURLING SLOTS)

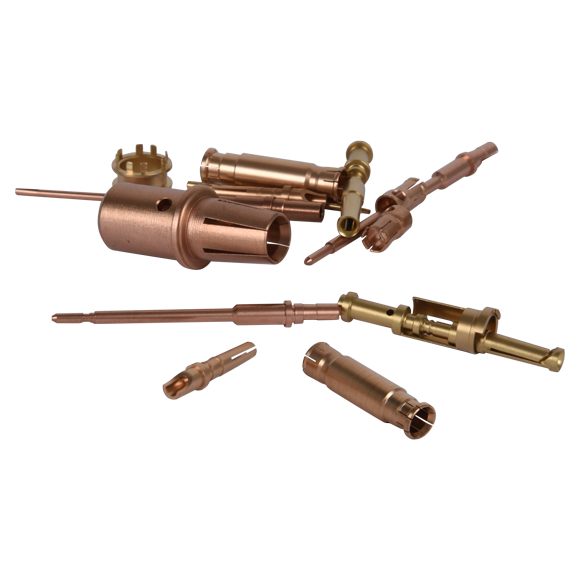

IDEAL FOR THE WATCHMAKING, MEDICAL, CONNECTIVITY, EQUIPMENTS, ETC..

- more than 200 machines at your disposal

- more than 100 tools and machines developed specifically for our customers

POLISHING / TRIBOFINISHING

I WANT IT LIKE THIS!

At Micro-Finish we always try our best. Our customers know that. Our technology can be adapted to a wide variety of parts and allows a great fineness of finish.

CHEMICAL-MECHANICAL POLISHING BY VIBRATIONS

- Roundings

- Smoothing

- Finishing and deburring of all micromechanical parts, turned parts ...

- All materials

BULK POLISHING

- Final roughness > N2

- + 60 vibrators of various technologies

- Appearance: according to your requirements

Control of different friction phenomena in a controlled environment.

Vibration in a tank with the addition of water and additives adapted to a customised finishing.

SANDBLASTING

Surface preparation and finishing by projection of abrasive materials.

To create roughness, adhesion, aesthetic finishings and surface preparation according to your needs. Matt appearance.

PROCESSING IN BULK OR PIECE BY PIECE

COMPLETE DEBURRING OF PARTS FOR CONNECTIVITY

COMPLETE, PARTIAL OR MASKED SURFACES

ROUGHNESS AND CONTROLLED APPEARANCE FOR VARIOUS SURFACE PREPARATIONS :

- friction drives

- special assemblies

- preparations for adhesions, etc.

ROUGHNESS MEASUREMENTS WITH TEST CERTIFICATES

MICROBEAD-BLASTING

The possible degree of roughness is vast and allows the realisation of contrasting, uniform or alternate finishings for selected aesthetics and applications.

Sample pads are available on site.

We have a special hall for the processing of large parts.

- Technical or visual finishing by projection of various beads.

- Shiny satin aspect.

- Preparation before eloxing aluminium or complete finishing of stainless steel parts.

QUALITY CONTROL

An efficient quality control, performed by specialised and qualified employees, guarantees the control and validation of the various parameters:

- Visual

- Dimensional

- Roughness

- Hardness

YOU RESPECT THE CERTIFICATIONS, HOPEFULLY?

Of course, this is a must particularly for the medical, chemical or aerospace sectors. We have set up a department dedicated to the medical sector and issue the necessary certificates of conformity.

CERTIFICATIONS RENEWED IN 2018:

- ISO 9001

- ISO 13485 (new international standards for quality management systems). They accompany our quality, comfort and safety procedures for our customers and employees.